- SIMATIC NET PC SOFTWARE V8.1 SP1 DOWNLOAD INSTALL

- SIMATIC NET PC SOFTWARE V8.1 SP1 DOWNLOAD DOWNLOAD

>Link Download Software ( GoogleDrive – High Speed Download ) SIMATIC NET is the foundation for network configuration and bus system configuration used in a SIMATIC project. + SIMATIC NET: Commissioning Wizard, Configuration Console and Station Configurator are SIMATIC NET interfaces. Process Objects View displays these objects and edits them right in the display mode. Process Objects View contains all the technical aspects of a project. + Process Objects View: in the engineering station, users can create multiple objects. Different from specific application libraries or other systems, a Master data library is in a Multiproject and sets all the functions used in the Multiproject. + Master Data Library: related to the Multiproject. A Multiproject can contain many small projects and a Master data library. + Multiproject: in SIMATIC Manager, users can initialize projects (single project or multiproject). + Station Configurator: shows the actual PC configuration found and configured for PCS 7 systems. The access sign always uses it to configure. + Configuration Console: With the Configuration Console, users can change these settings after the Commissioning Wizard launches.

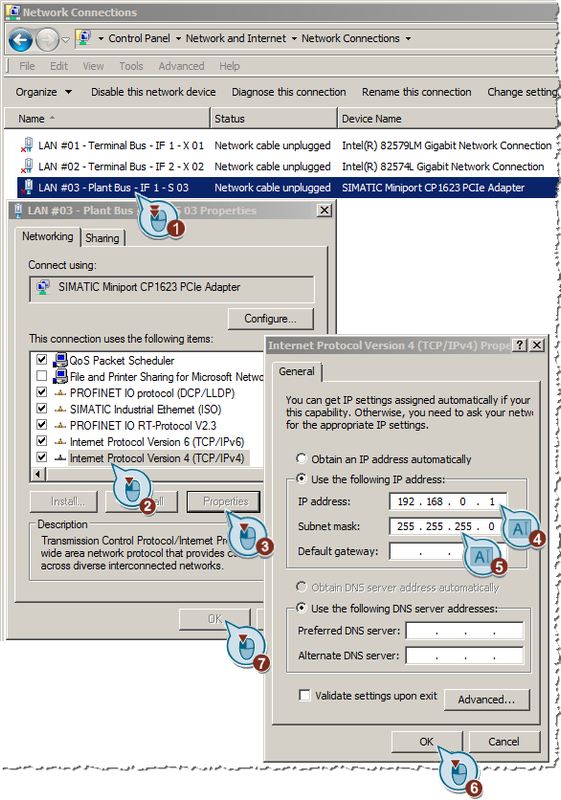

SIMATIC NET PC SOFTWARE V8.1 SP1 DOWNLOAD INSTALL

+ Commissioning Wizard: when the PC restarts, the program automatically detects newly installed SIMATIC Modules and guides users step by step to install and configure the PC station. + Graphics Designer Editor: design graphic objects, images and animations. system announcements, signal graphs, operating logs … visually interface the entire operation process of the system visually. With this software, you can create process pictures, reports, and reports. + WinCC (Windows Control Center): WinCC is used for the configuration of factory monitoring and control systems based on PCS 7. + IEA (Import Export Assistant): Generates control models. On ES, it is used to create blocks and compile CFC / SFC chart requirements. + SCL (Structured Control Language): This is the same programming language as Pascal to program for complex tasks. With a sequential control system, the basic target automation function is controlled on state changes and also selectable from the process. + SFC (Sequential Function Chart): A software package configured for sequential control systems. Blocks are grouped according to their function in the library, performing programming using drag / drop gestures. Use CFC through pre-made blocks (this is a structured programming package).

+ CFC (Continuous Function Chart): CFC is a factory-oriented software package that configures automation graphics. + HW Config: hardware configuration for the CPU, media addressing, peripheral devices and field buses … PH supports wide-area configuration of plant data control and management processes. + PH (Plant Hierarchy): design of plant hierarchy. With SIMATIC Manager we can create projects, create libraries, manage and diagnose project components, store project objects … SIMATIC Manager is often used to manage factory projects. + SIMATIC Manager: this software is the foundation and management center for all components of the technical station, which is the link of the entire project.

PCS7 also supports and uses standard software interface technologies such as DDE-dynamic data exchange (Dynamic Data Exchange), OLE (Object Linking and Embedding), ActiveX, ODBC extended database connection ( Open DataBase Connection), and OPC (OLE for Process Control). The communication network can select the protocols: Industrial Ethernet, Fast Industrial Ethernet, PROFIBUS, AS-i, HART. PCS 7 uses common technology, international standardization, so the ability to coordinate with other systems and equipment is not limited in width and depth. + Spend less effort and time on programming, repairing, commissioning, and maintaining the system. + SIMATIC PCS 7 can be used in all process control areas. + Access management through user administration. + Reporting, recording, and archiving systems. + There is redundancy for all components. + Tactics for booting and rebooting the entire system or just the individual components. + Check operation and diagnose all components of the system. + SIMATIC PCS 7 provides the best possible support for system configuration for process automation tasks. + When components work in a combination, they work together in a unified manner, and match the features of the SIMATIC product line. SIMATIC PCS 7 is a combination of process control system functions and the SIMATIC product line, designed to work together as a homogeneous relationship of the system. PCS 7 was developed based on the products in the SIMATIC family. It is the result of system development and integration from the experience of previous systems such as TELEPERM M, SIMATIC S7, SIMATIC S5. SIMATIC PCS 7 is a process control system of SIEMENS. PCS-7 is the overall integrated automation solution for process control systems

0 kommentar(er)

0 kommentar(er)